Simple and user-friendly configuration of the required measurement parameters, front screen heating to prevent condensation on the optics, selectable laser clocking for a long service life and safe operation offer you maximum safety and reliability.

The compact and robust design, as well as the low weight, predestine the application location, e.g. directly at the highest point of your weather protection membrane.

With non-contact laser distance measurement, you are ideally positioned for future requirements in the biogas and sewage treatment plant sector!

Already tried and tested many times in use!

At the beginning of 2020, we have started a project in the biogas industry for contactless gap and distance measurement between membranes in fermenters, digestion towers, repositories and gas storage facilities. As a solution, we are using a laser distance sensor, which has been extensively tested in the course of the project and in cooperation with well-known biogas roof manufacturers and several biogas plant operators. While this process the laser distance sensor has been further developed for the required demands.

Systems and sensors that have been used so far working with or without contact are not reliable nor accurate enough. In this context, draw-wire sensors, hydrostatic measuring systems, ultrasonic sensors or radar technology are repeatedly mentioned.

Our laser measurement has proven itself in many ways and has become a standard solution for biogas roof manufacturers and numerous end customers and their specific measurement tasks.

All necessary Ex approvals for worldwide use are available and offer you the highest level of safety and reliability.

A further application for our laser distance sensor is the level measurement of waste water or solids, e.g. on rake systems in sewage treatment plants (mechanical cleaning)." Due to the focussed laser beam, the sensor can also be installed near concrete walls. Agitators, pipes, etc. do not affect the measurement. Sensors that work on touch, e.g. immersion probes, must be serviced regularly (cleaning, etc.). While using our laser distance sensor this entire processing step is eliminated and the maintenance effort and eventually the costs can be significantly reduced.

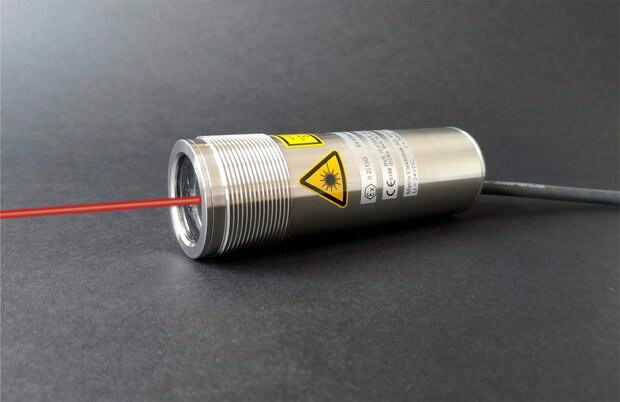

Please find below some technical data for your initial information:

- Measuring principle: transit time measurement

- Light used: Laser light in red, laser class 2

- Scanning distances: 0.05 m - 30 m, this can be programmed to the required measuring range

- Area of application: Ex zone 1, 2 - devices may also look into zone 0 due to the OP approval

- Power supply: 24 VDC

- Outputs: 4-20mA and RS-485

- Design: M 42, protection class IP 67

- Ex type of protection: Ex d (flameproof enclosure)